Trilogical exhibited and served as a sponsor at Rail Research Week 2025 – the landmark convergence of the International Heavy Haul Association Conference (IHHA 2025) and the World Congress on Railway Research (WCRR 2025) – which took place November 17–21, 2025 in Colorado Springs.

The week’s theme, “Inspiring Innovative and Resilient Railways,” set the stage for a global exchange of ideas spanning freight and passenger rail.

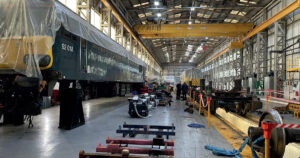

At Rail Research Week, Trilogical showcased two flagship platforms – Control FREAK for locomotive and multiple-unit remote condition monitoring and diagnostics, and RailBlazer telematics for freight and mining rail logistics – both closely aligned with the event’s key industry priorities, including network capacity and operational efficiency, long-haul train operations, safety and derailment prevention, condition monitoring, and detector-based maintenance enhanced by big-data analytics.

Control FREAK: from detection to prediction

Rail operations have long depended on after-the-fact alerts that triggered only when failures occurred, leaving teams to respond without the context needed to prevent recurrence. Control FREAK changes that paradigm. The platform continuously collects rich subsystem data – paired with operational context such as speed, load, temperature, and location – enabling engineers to analyse what happened, why it happened, and how to prevent it. With high-quality, continuous data in place, AI-driven anomaly detection and health indicators enabled forecasting of failures before they occurred, while cross-functional teams (operations, maintenance, engineering) collaborated around a single source of truth.

The result is a systematic shift from reactive troubleshooting to proactive reliability: instead of isolated sensor traces at the moment of failure, operators gain a longitudinal view of fleet health that supported top-down investigations and bottom-up sensor analysis – turning every incident into an opportunity to harden systems and reduce lifecycle costs.

RailBlazer: turning freight and mining rail logistics into a competitive advantage

Rail freight operations – whether serving national networks or dedicated mining corridors – depended on efficient, uninterrupted movement of goods. Yet disruptions, limited visibility, and rising costs often undermine performance and throughput. RailBlazer addresses these challenges head-on, combining real-time monitoring, predictive analytics, and supply-chain integration to deliver measurable results – such as up to a 20% improvement in overall logistics efficiency, based on industry benchmarks and projected gains from telematics adoption.

RailBlazer drives value across six focus areas: reliability and uptime (condition-based maintenance with predictive analytics), safety and compliance (derailment-risk detection, overload prevention, automated reporting), efficiency and productivity (trip analytics, turnaround optimization, fuel-aware dispatching), asset utilization and visibility (fleet tracking and utilization dashboards), cost reduction (downtime avoidance and energy insights), and integration (API-based connectivity with TMS and ERP systems for coordinated decisions).

Rail operators told us they want fewer surprises and more foresight. By unifying continuous data collection with practical analytics, Control FREAK and RailBlazer help teams anticipate issues, optimize resources, and operate with greater resilience – directly in line with the mission of Rail Research Week.

Trilogical’s Train Intelligence platforms drew strong interest from industry peers, particularly those focused on heavy haul operations, who explored how telematics and advanced analytics can address the sector’s most pressing challenges by converting operational data into measurable improvements in uptime, safety, and sustainability across the world’s most demanding freight networks.