The Erosion of Rail Freight Performance

In freight rail operations, profitability is closely tied to asset velocity. Every railcar is expected to move, generate revenue, and return to service with minimal dwell. When a railcar goes out of service unexpectedly, the impact extends far beyond a single mechanical issue. Downtime quietly erodes network efficiency, disrupts schedules, and introduces costs that accumulate long before they appear on a balance sheet.

Unplanned railcar downtime is rarely caused by a single event. It is typically the result of limited visibility into fleet condition, delayed fault detection, lost or misrouted cars, and maintenance actions triggered too late. Without continuous, real-time insight into railcar location, load status, and health indicators, operators are forced to react rather than prevent, allowing minor issues to escalate into service-affecting failures.

As rail networks push to reduce dwell time and maximize throughput, downtime has become more than a maintenance concern. It is now a measurable operational and financial risk that directly influences asset utilization, service reliability, and customer confidence.

How Downtime Accumulates: The True Cost of an Idle Railcar

The financial consequences of a sidelined railcar begin immediately. Missed cycles translate into lost revenue, while recovery efforts introduce additional operational friction. For both Class I and short line operators, even a single unavailable railcar can trigger a chain reaction across yards, terminals, and mainline operations.

A common scenario illustrates the problem clearly: one defective car within a trainset forces an unscheduled stop or set out. What begins as a localized issue quickly expands into network-wide disruption. The resulting costs typically include:

- Demurrage and penalty charges when loading or unloading windows are missed

- Lost throughput from delayed or cancelled revenue-generating movements

- Yard congestion and inefficient crew utilization caused by rescheduling and re-blocking

- Reduced service reliability that weakens shipper confidence and long-term commercial relationships

These impacts are compounded when railcars are not continuously monitored. Without precise location data, condition awareness, and event history, operators lose valuable time locating faulty assets, diagnosing issues, and dispatching maintenance resources. Manual processes extend dwell, while uncertainty increases operational risk.

Why Visibility Is Central to Reducing Downtime

Downtime is not only the result of failure; it is often the result of delayed awareness. Real-time railcar telematics directly addresses this gap by turning each railcar into a continuously visible, digitally monitored asset.

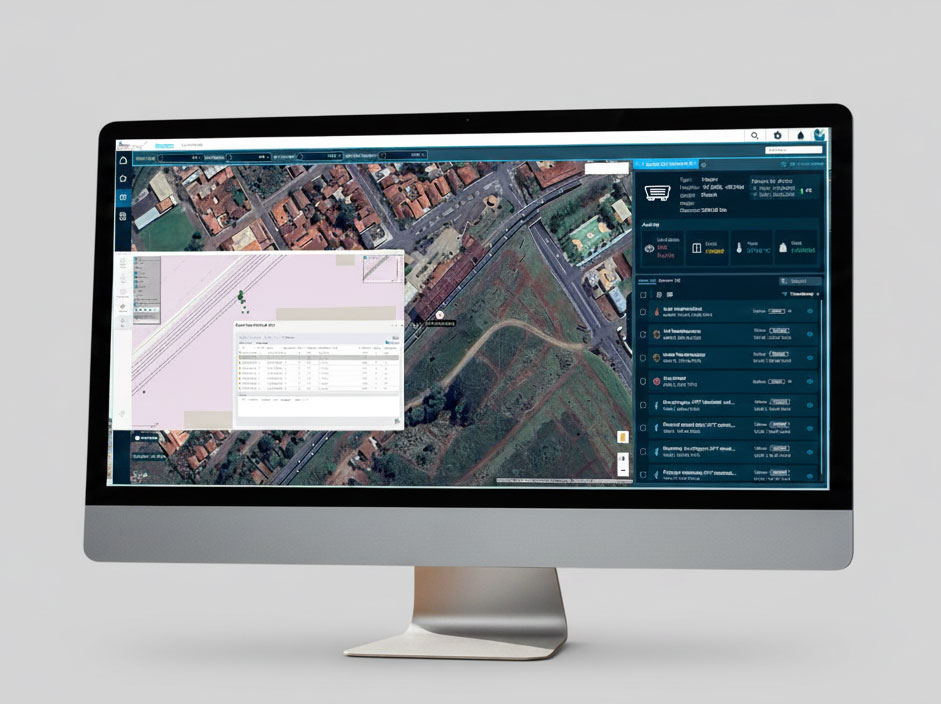

With RailBlazer by Trilogical, operators gain persistent insight into where each railcar is, whether it is loaded or empty, how it has been handled, and whether abnormal events have occurred. Advanced load and impact monitoring capture damaging coupling forces and excessive shocks within milliseconds, while vibration-based health analytics identify early-stage defects such as wheel flats before they trigger service removals.

Handbrake-related incidents remain a frequent and often underestimated contributor to unplanned downtime. Railcars moving with engaged handbrakes can cause overheating, excessive wheel wear, flats, and in severe cases, forced removals from service. Conversely, improperly released handbrakes in yards and terminals introduce safety risks and operational delays. Continuous handbrake status monitoring closes this visibility gap by allowing operators to identify improper handbrake conditions in real time, intervene early, and prevent avoidable damage and service disruptions.

Track-level location accuracy provided by the RailBlazer enables precise positioning within yards and terminals, reducing time lost searching for assets or resolving disputes over car availability. Mileage tracking supports condition- and usage-based maintenance, allowing service intervals to be optimized rather than dictated by fixed schedules or late-stage failures.

By shortening the time between event occurrence, detection, and response, telematics reduces diagnostic delays, minimizes unproductive dwell, and prevents isolated incidents from escalating into network disruptions.

From Reactive Recovery to Predictable Performance

Railcar downtime cannot be eliminated entirely, but it can be controlled. The difference lies in whether operators discover problems after service is disrupted or before it occurs.

Load-related uncertainty is another factor that amplifies downtime risk and operational inefficiency. Without reliable insight into whether railcars are empty, partially loaded, or overloaded, operators face increased exposure to damage, non-compliance, and inefficient asset cycling. Additionally, RailBlazer’s proprietary weight estimation capability provides continuous load status visibility without relying on external infrastructure. This enables early detection of overloading, supports ton/mile-based performance analysis, and improves maintenance planning by correlating load conditions with impact, vibration, and wear patterns.

RailBlazer enables a shift from reactive recovery to predictable performance. Continuous monitoring replaces assumptions with data, while automated alerts and historical analytics support faster decisions and more efficient resource allocation. Maintenance teams are directed to the right car at the right location, operations teams maintain situational awareness across the fleet, and planners gain accurate inputs for utilization and cycle-time optimization.

The result is measurable: reduced downtime, improved asset availability, lower maintenance costs, and stronger service reliability – all of which directly contribute to improved profitability.

Reliability as a Financial Strategy

Every hour of railcar downtime carries a cost, whether visible or hidden. Lost revenue, inefficiency, and customer dissatisfaction are not isolated side effects; they are direct outcomes of limited visibility and delayed response.

Maintaining continuous railcar monitoring coverage is no longer a technical upgrade. It is a strategic operational decision that influences utilization, velocity, and return on assets. In an environment where margins are increasingly defined by efficiency rather than scale, telematics has become a foundational tool for protecting profitability and sustaining long-term network performance.

By combining real-time location and handbrake status monitoring, load estimation, and health analytics, railcar telematics transforms downtime from an unpredictable cost into a controllable operational variable.

RailBlazer does not eliminate the risks inherent in freight rail operations. It makes them measurable, manageable, and significantly less costly.