For decades, rail operations relied on sensors that triggered alerts only after a failure occurred. This reactive culture left engineers scrambling to replace components without truly understanding the root causes. The result: repeated incidents, rising maintenance costs, and avoidable operational downtime.

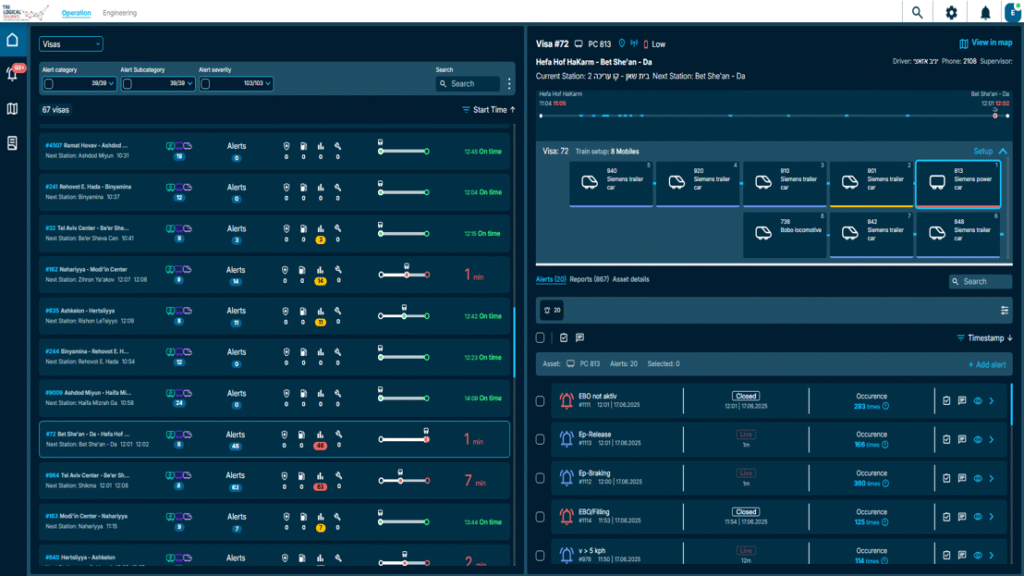

Trilogical’s Control FREAK Remote Condition Monitoring & Diagnostics platform for locomotives and MUs changes this paradigm. Step by step, it moves from late failure detection to structured analysis, continuous data collection, and ultimately data-driven prediction – building a culture of proactive reliability.

Consider a real case late one evening. At 10:12 p.m., the Control Center received an electrical failure alert from a passenger locomotive. The staff on duty, already familiar with this type of failure, guided the driver through procedures to keep the train safe and operational. The following morning, the head of the Rolling Stock Engineering demanded an immediate investigation and corrective measures to prevent recurrence. Engineers once again found that a capacitor had failed. Yet critical questions remained: Why did it fail? When could it have been detected? What was the root cause?

This case illustrates the limits of traditional systems. Detection came too late, and the few available sensor readings captured only fragments seconds before and after the event. These traces offered little useful information. When the AI team was asked to assist in the analysis, they quickly realized the necessary data simply did not exist.

Control FREAK addresses precisely this gap. Rather than focusing only on alerts, it allows engineers to review detailed sensor data, environmental conditions, and system performance leading up to a failure. This enables them to determine not just what failed, but why it happened, whether it might recur, and what systemic weaknesses may exist across the fleet.

At the core of this transformation is comprehensive data collection. Control FREAK continuously gathers information from critical subsystems – current consumption during door cycles, vibration signatures from engines, acoustic patterns from mechanical movements – and enriches it with operational context such as speed, load, temperature, and location. Together, these create a digital record of fleet health, stored in the cloud for long-term access and enabling both top-down investigations and bottom-up sensor analysis.

With high-quality, continuous data available, prediction becomes achievable. AI is no longer the hardest part; it becomes the natural outcome. Control FREAK applies advanced algorithms to identify anomalies, generate subsystem health indicators, and forecast failures before they occur. Engineers can also define custom rules, establishing new thresholds and flags when emerging symptoms appear. This makes the platform flexible and adaptive, evolving alongside operational experience.

What emerges is not merely a new tool but a cultural shift. Control FREAK integrates operational, maintenance, and engineering domains within a single platform, delivering valuable insights to all stakeholders. Instead of working in silos, teams collaborate using shared information, investigating problems from multiple directions – from subsystem failures down to components, or from unusual sensor patterns up to fleet-wide impact. Every incident becomes a learning opportunity, feeding back into the data lake and strengthening predictive capabilities.

The journey from detection to prediction is one of evolution. Control FREAK enables operators to move beyond reacting to failures, toward understanding, preventing, and ultimately avoiding them. By combining engineering expertise with continuous data and AI, it builds resilience, reduces maintenance costs, and ensures safer, more reliable operations. This is how the Control FREAK solution transforms rail fleets into smarter, future-ready assets.